PEHD PE100RC/PP

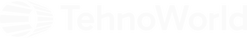

High density polyethylene pipes with exfoliating polypropylene protective layer are manufactured according to SR EN 12201-2:2011+A1:2013 Annex C. The inner layer is black, made of PE 100 RC and the outer layer is colored blue, made of PP.

Polyethylene pipes with exfoliating PP protective layer are used both for drinking water supply networks and for raw water transport networks (meteor water, underground water, water from rivers, lakes, etc.). Before the treatment process , PE 100 RC pipes with PP protective layer can also be used in fire extinguishing systems with hydrants, designed according to national standards, as well as in piping systems for industrial applications according to EN ISO 15494 and ISO/TR 10358, due to the increased chemical resistance of the material. The polypropylene protective layer has only a protective role and does not influence the mechanical characteristics of the pipe.

PE 100 RC polyethylene pipe with PP protective layer is distinguished by the fact that it can be installed by alternative laying methods without a sand bed or a mandatory laying in trenches, directional drilling and rehabilitation of existing pipes. These pipes are highly resistant to crack propagation under the action of high loads, ensuring an increase in lifetime.

Advantages of the protective layer:

· The outer PP layer protects the pipe during handling, transportation and installation;

· Prevents contamination of the pipe surface with dirt and oxidation;

· High mechanical resistance - provides excellent scratch resistance;

· Protecting the pipe from scratches and impurities excludes the risk of errors when welded, head-to-head or electrofusion;

· Protects the pipe against sunlight, thus contributing to increase the time of storage and longevity;

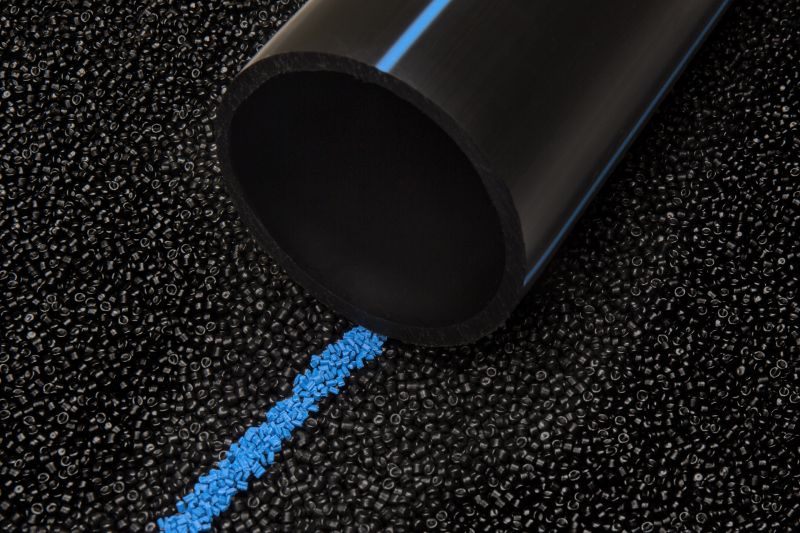

The range of diameters is between ⌀63÷⌀1200.

Catalog

- PEHD PE 100 RC PP (PDF)

Technical manuals

- Technical data sheet (PDF)

Technical approval

- Health certificate - Republic of Moldova (PDF)

- Technical Notice (PDF)

- Health certificate (PDF)

- Technical approval (PDF)

- Health Certificate - Ukraine (PDF)

Certifications

PEHD PE100/PP apă

High density polyethylene pipes with exfoliating polypropylene protective layer are manufactured according to SR EN 12201-2:2011+A1:2013 Annex C. The inner layer is black, made of PE 100 and the outer layer is colored blue, made of PP.

Polyethylene pipes with exfoliating PP protective layer are used both for drinking water supply networks and for raw water transport networks (meteor water, underground water, water from rivers, lakes, etc.). Before the treatment process , PE 100 pipes with PP protective layer can also be used in fire extinguishing systems with hydrants, designed according to national standards, as well as in piping systems for industrial applications according to EN ISO 15494 and ISO/TR 10358, due to the increased chemical resistance of the material. The polypropylene protective layer has only a protective role and does not influence the mechanical characteristics of the pipe.

PE 100 polyethylene pipe with PP protective layer is distinguished by the fact that it can be installed by alternative laying methods without a sand bed or a mandatory laying in trenches, directional drilling and rehabilitation of existing pipes. These pipes are highly resistant to crack propagation under the action of high loads, ensuring an increase in lifetime.

Advantages of the protective layer:

· The outer PP layer protects the pipe during handling, transportation and installation;

· Prevents contamination of the pipe surface with dirt and oxidation;

· High mechanical resistance - provides excellent scratch resistance;

· Protecting the pipe from scratches and impurities excludes the risk of errors when welded, head-to-head or electrofusion;

· Protects the pipe against sunlight, thus contributing to increase the time of storage and longevity;

The range of diameters is between ⌀63÷⌀1200.

Catalog

- PEHD PE 100 PP (PDF)

Technical manuals

- Fiche technique (PDF)

Technical approval

- Technical Notice (PDF)

- Health certificate (PDF)

- Health certificate - Republic of Moldova (PDF)

- Technical approval (PDF)

- Health Certificate - Ukraine (PDF)